- Joined

- Aug 7, 2007

- Messages

- 97

- Reaction score

- 79

- Points

- 18

- Age

- 39

- Location

- SW Iowa

- Vehicle Year

- 2022

- Vehicle

- Ford

- Engine Size

- 2.3

- Suspension Style

- 4wd

Original Poster: 85_Ranger4x4

Difficulty: 2 out of 10

Time to install: 20 minutes

Disclaimer: The Ranger Station.com, The Ranger Station.com Staff, nor the original poster are responsible for you doing this modification to your vehicle. By doing this modification and following this how-to you, the installer, take full responsibility if anything is damaged or messed up. If you have questions, feel free to PM the original poster or ask in the appropriate section of The Ranger Station.com forums.

Brief Explanation: How to install a Curt 13493 Receiver Hitch kit on a 2021+ Ford Bronco. It is a pretty easy project to avoid the currently constrained tow package especially if you just want a receiver for a recovery point or for cargo like a bike rack or hitch carrier. Wiring kits are offered if you do want trailer lights too (I am not currently planning on adding that)

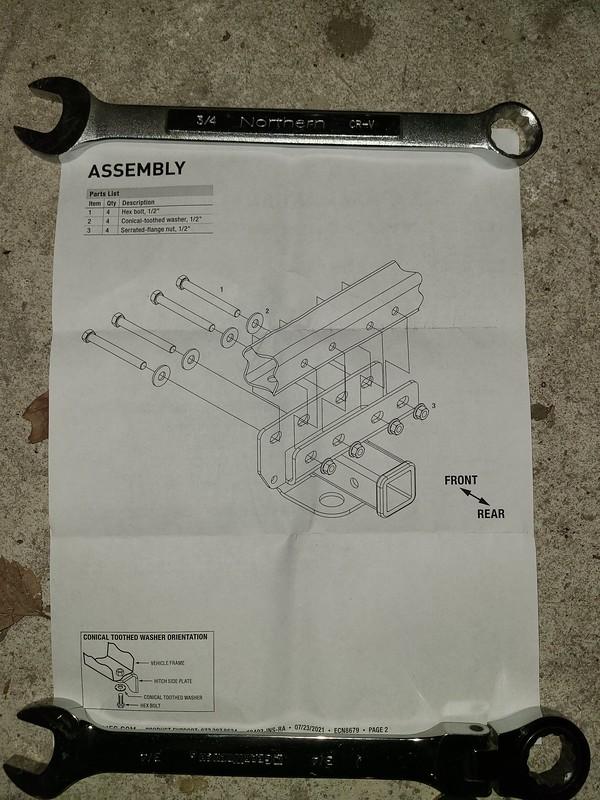

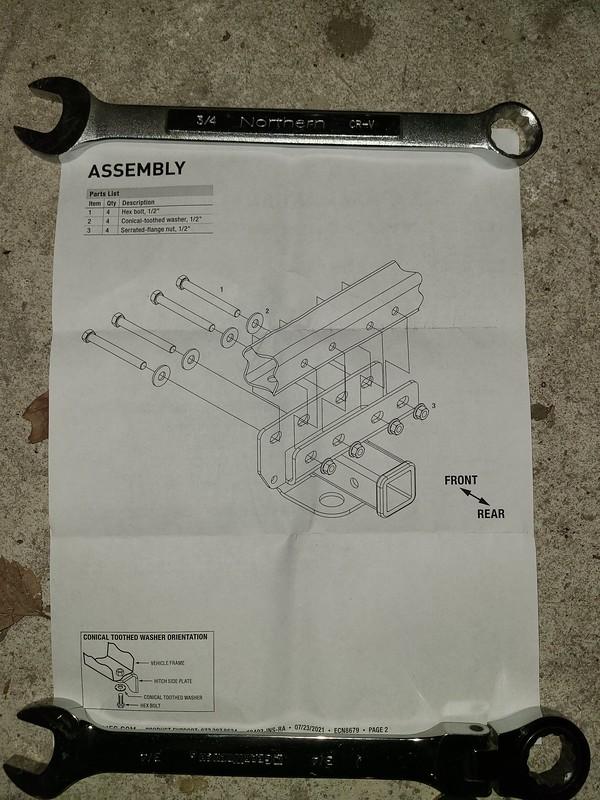

Tools Needed:

- 3/4" combination wrench

- 3/4" socket/ratchet OR a 3/4" ratcheting wrench

- Flashlight (optional but very helpful)

Parts Needed:

- Curt Receiver Hitch Kit 13493 (I would suspect most receiver hitch kits for this application will mount the same)

---------------------------------------------------------

Steps 1: Locate the four holes in the rear crossmember between the muffler and the rear bumper.

Install the receiver on those for holes, start with the two end bolts (with washers!) fished thru to hold the receiver in place. The heads go from the front of the truck and the nuts come on from the rear of the truck (towards the rear bumper)

---------------------------------------------------------

Steps 2: Get all the bolts in. It will take a little finagling to get them in the holes because the muffler is tight to the crossmember. Be sure to leave the hitch loose so you can wiggle it around.

---------------------------------------------------------

Steps 3: With all the bolts in get started with the nuts. It is pretty tight between the bumper supports and the crossmember for the hitch and it takes some dexterity to get things going.

The inside two were a bugger and them being flange nuts with a big flange made them hard to hang onto. So I stuck them in the box end of my ratchet wrench.

---------------------------------------------------------

Step 4: Tighten them down. Directions say 110lb-ft but good luck getting a torque wrench on them, pretty much get them as tight as you can with a wrench and recheck frequently for awhile to make sure they stay tight. And then you are done!

Difficulty: 2 out of 10

Time to install: 20 minutes

Disclaimer: The Ranger Station.com, The Ranger Station.com Staff, nor the original poster are responsible for you doing this modification to your vehicle. By doing this modification and following this how-to you, the installer, take full responsibility if anything is damaged or messed up. If you have questions, feel free to PM the original poster or ask in the appropriate section of The Ranger Station.com forums.

Brief Explanation: How to install a Curt 13493 Receiver Hitch kit on a 2021+ Ford Bronco. It is a pretty easy project to avoid the currently constrained tow package especially if you just want a receiver for a recovery point or for cargo like a bike rack or hitch carrier. Wiring kits are offered if you do want trailer lights too (I am not currently planning on adding that)

Tools Needed:

- 3/4" combination wrench

- 3/4" socket/ratchet OR a 3/4" ratcheting wrench

- Flashlight (optional but very helpful)

Parts Needed:

- Curt Receiver Hitch Kit 13493 (I would suspect most receiver hitch kits for this application will mount the same)

---------------------------------------------------------

Steps 1: Locate the four holes in the rear crossmember between the muffler and the rear bumper.

Install the receiver on those for holes, start with the two end bolts (with washers!) fished thru to hold the receiver in place. The heads go from the front of the truck and the nuts come on from the rear of the truck (towards the rear bumper)

---------------------------------------------------------

Steps 2: Get all the bolts in. It will take a little finagling to get them in the holes because the muffler is tight to the crossmember. Be sure to leave the hitch loose so you can wiggle it around.

---------------------------------------------------------

Steps 3: With all the bolts in get started with the nuts. It is pretty tight between the bumper supports and the crossmember for the hitch and it takes some dexterity to get things going.

The inside two were a bugger and them being flange nuts with a big flange made them hard to hang onto. So I stuck them in the box end of my ratchet wrench.

---------------------------------------------------------

Step 4: Tighten them down. Directions say 110lb-ft but good luck getting a torque wrench on them, pretty much get them as tight as you can with a wrench and recheck frequently for awhile to make sure they stay tight. And then you are done!

Last edited: