McWillies

Member

- Joined

- Aug 30, 2017

- Messages

- 65

- Reaction score

- 16

- Points

- 8

- Age

- 25

- Location

- Louisiana

- Vehicle Year

- 1989

- Vehicle

- Ford Bronco II

- Engine Size

- 2.9l

- Suspension Style

- 4wd

I have a custom 170amp 3g alternator on the way and I've just been toying around with the idea of dual alternators (2.9), in my head. Not really planning to actually do it, but the idea is interesting.

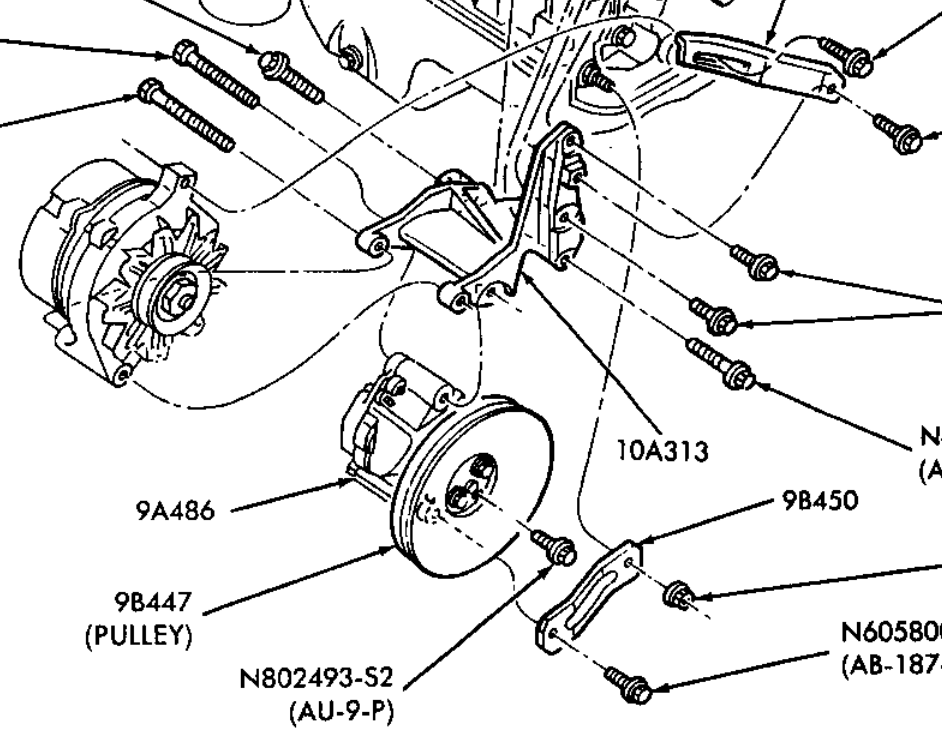

On 2.9s with a smog pump, the bracket on the passenger side for the alternator was slightly different, to mount the pump underneath it.

If you've ever pulled that bracket off, you probably recognize the diagram, but most of the 2.9s didn't come with a smog pump from what I understand, so that part may seem foreign... It does to me at least. Another weird thing you might notice is the alternator front cover has mounting points 180 degrees apart (maybe a slight difference on models with a smog pump?). My 2.9 takes an alt with a 2 o'clock adjusting ear.

The pivot mount on top of the smog pump is very similar to the pivot mount on the bottom of the alternator, but the alternator one is slightly thicker (front-to-back) I believe. This shouldn't be a major setback because the mounting tabs on the bracket have quite a bit of thickness to them, so shaving it a quarter inch or so, to open up the gap between the two mounts, would be fine structurally. Making sure the bottom alt pulley is in line with the others may be a bit tricky, though.

Looking back at a picture of the bracket on my engine, It looks like there aren't holes drilled on the two mounting tabs. Here's a good picture of one that I found:

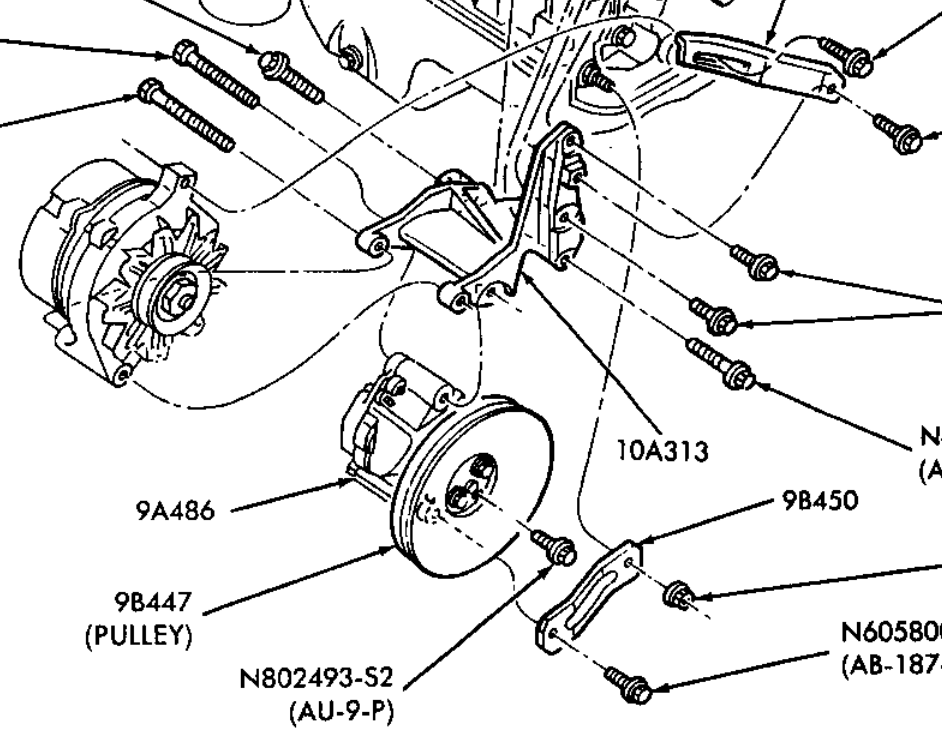

The bracket is upside down from how it would be mounted, but this is the rear mounting tab, with no hole drilled.

Here's the front one, same story. You can see the flanges are pretty thick though.

You can also see the tabs are offset quite a bit horizontally from the alternator lower mount. This isn't a bad thing in my opinion as I'd probably wanna run the two alts on different belts; that way I don't lose both alts if one belt fails. Obviously the alternator front housing would have to be clocked so that the swivel is on top, but that shouldn't be a problem. As for the second mounting point, something very similar to the original alternator mounting could be used, but the hole wouldn't have to be oblonged because the belt can be tensioned elsewhere.

This is just my brain running through different things. Let me know what y'all think, thanks.

On 2.9s with a smog pump, the bracket on the passenger side for the alternator was slightly different, to mount the pump underneath it.

If you've ever pulled that bracket off, you probably recognize the diagram, but most of the 2.9s didn't come with a smog pump from what I understand, so that part may seem foreign... It does to me at least. Another weird thing you might notice is the alternator front cover has mounting points 180 degrees apart (maybe a slight difference on models with a smog pump?). My 2.9 takes an alt with a 2 o'clock adjusting ear.

The pivot mount on top of the smog pump is very similar to the pivot mount on the bottom of the alternator, but the alternator one is slightly thicker (front-to-back) I believe. This shouldn't be a major setback because the mounting tabs on the bracket have quite a bit of thickness to them, so shaving it a quarter inch or so, to open up the gap between the two mounts, would be fine structurally. Making sure the bottom alt pulley is in line with the others may be a bit tricky, though.

Looking back at a picture of the bracket on my engine, It looks like there aren't holes drilled on the two mounting tabs. Here's a good picture of one that I found:

The bracket is upside down from how it would be mounted, but this is the rear mounting tab, with no hole drilled.

Here's the front one, same story. You can see the flanges are pretty thick though.

You can also see the tabs are offset quite a bit horizontally from the alternator lower mount. This isn't a bad thing in my opinion as I'd probably wanna run the two alts on different belts; that way I don't lose both alts if one belt fails. Obviously the alternator front housing would have to be clocked so that the swivel is on top, but that shouldn't be a problem. As for the second mounting point, something very similar to the original alternator mounting could be used, but the hole wouldn't have to be oblonged because the belt can be tensioned elsewhere.

This is just my brain running through different things. Let me know what y'all think, thanks.