Table of Contents:

- Self-Diagnostics Terminal Setup (1)

- Code erasing (2)

- Two Digit Test Codes (3)

- Three Digit Test Codes (4)

- Abbreviations and Definitions (5)

- TPS Calibration (6)

- Base Idle Adjustment (7)

- Oxygen Sensor Testing (8)

- TFI Module Testing (9)

- ACT/ECT Test (10)

- TFI Timing Procedure (11)

- IAC Cleaning and Testing (12)

- FPR Testing (13)

- Knock Sensor (14)

- MAP Test (15)

Self-Diagnostics Terminal Setup (1)

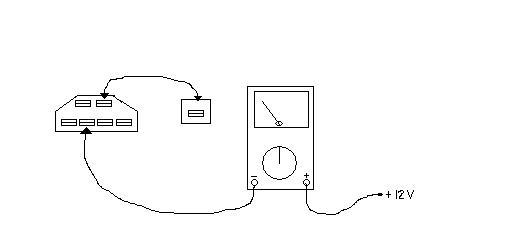

On the passenger’s side, under the hood, there is the computer’s self-diagnostics output terminal. It is usually red or gray in color, and has a distinctive shape as shown below. An easy way to utilize this terminal without an expensive scan tool is with an analog multi-meter, set on DC Voltage (20V setting, or nearest equivalent). The Positive lead of the multi-meter can be attached to the battery’s (+) terminal, and the negative lead of the multi-meter can be attached to the connection as below. A jumper wire is also necessary (as below).

Scanning the codes. You want to make sure the engine is fully warmed up, automatic transmission in park, or manual transmission in neutral, with the parking brake on, or the wheels blocked. Once the multi-meter is attached, turn the ignition on, and watch the needle. Codes will be displayed as needle sweeps in groups of 2 or 3, followed by a 6 second delay. A 2 or three digit code will be several quick sweeps (1-9) followed by a 1 second pause, than the next number. These are referred to as memory codes. This test is complete when code 11 (system pass) has been displayed.

Running codes are done after this. The engine is started and left running. The code reader will flash twice (for a four cylinder) three times (for a 6 cylinder), four times (for and 8 cylinder), and five times (for a diesel). The computer will test items, including the timing. A timing light may also bee hooked up, and the timing should advance by 20 degrees during this test. Eventually there will be a single quick sweep of the needle; this is the throttle goose test. When this happens, the throttle must be depressed (a minimum) of 25%. The codes will be soon to follow, as per the previous test.

Erasing Codes (2)

Codes automatically erase after 60-100 starts. Starting the memory test procedure, and unplugging the connections erases memory codes. Disconnecting the battery will also erase all the codes; however, this may trigger a code 19 (loss of PCM power).

Two Digit Codes: (3)

-

- (O) = Key On Engine Off test

- (R) = Key On Engine Running test

- (M) = Memory code

11 – System checks OK

12 – Idle Speed Control motor or Air Bypass not controlling idle properly (generally idle too low) – ISC

13 – (O) ISC did not respond properly (extends to touch throttle then retracts for KOEO) – ISC

(R) Idle Speed Control motor or Air Bypass not controlling idle properly (generally idle too high)

(M) ISC sticking, open ITS circuit or TP sticking

14 – Ignition pickup was erratic – Ignition Systems

E4OD Transmission diesel RPM sensor – Diesel RPM sensor

15 – (O) No Keep Alive Memory power to PCM pin 1 or bad PCM (Memory Test Failure)

(M) KAM (pin 1) was interrupted (was battery disconnected ?)

16 – 1.9L & 2.5L – Throttle stop set too high – IDLE or Idle Set Procedures

2.3L – RPM’s too low – IDLE

(O) Electronic ignition – IDM circuit fault – Ignition Systems

17 – 1.9L & 2.5L – Throttle stop set too low – IDLE

18 – (R) Check base timing & advance function – Timing Tests

(M) Ignition TACH signal erratic – Ignition Systems

19 (O) No Vehicle Power (pins 37 + 57) or bad PCM VPWR Diagnosis

(R) Erratic idle during test (reset throttle & retest) – Idle Set Procedures

Electronic ignition Cylinder ID sensor/circuit problem – Ignition Systems

21 – Engine Coolant Temperature (ECT) sensor out of range – ECT

22 – MAP (vacuum) or BARO signal out of range – MAP

23 – Throttle sensor out of range or throttle set too high – TPS

24 – Intake Air Temperature (IAT) or Vane Air Temperature (VAT) sensor out of range – IAT VAT

25 – Knock sensor not tested (ignore if not pinging) – KS

26 – Mass Air Flow (MAF) or Vane Air Flow (VAF) out of range – MAF VAF

Transmission Oil Temperature (TOT) sensor out of range – Transmissions

27 – Vehicle Speed Sensor problem – VSS

28 – Vane Air Temperature (VAT) sensor out of range – VAT

2.3L w/Electronic Ignition – Cyl ID, IDM low or right coil pack failure – Ignition Systems

29 – Vehicle Speed Sensor problem – VSS

EGR CODES DEPEND ON WHAT SYSTEM TYPE THE VEHICLE IS EQUIPPED WITH:

EVP is for vehicles equipped with EGR solenoid(s), with or without an EVP sensor

EVR is for vehicles equipped with an EGR Vacuum Regulator (EVR) and an EGR Valve Position (EVP) sensor

PFE is for vehicles with Pressure Feedback EGR (PFE) sensor and and an EGR Vacuum Regulator (EVR)

If you don’t know what type of system you have, go to the EVP heading, which is the first one.

There are pictures under the different headings to help you identify the system.

31 – EVP – (O, R, M) EVP signal is/was out of range – EVP

EVR – (O, R, M) EVP signal is/was low – EVR

PFE – (O, R, M) PFE signal is/was low – PFE

32 – EVP – (R) EGR not responding properly during test – EVP

EVR – (O, R, M) EVP signal is/was low – EVR

PFE – (R, M) PFE shows low pressure, EGR not seating or memory, not seating intermittently – PFE

33 – ALL – (O, M) EGR did not open/ respond during test or if memory code, did not open intermittently – EVP EVR PFE

34 – EVP – (R) EGR did not respond properly during test – EVP

EVR – (O, R, M) EVP sensor is/was high – EVR

PFE – (O, R, M) PFE sensor is/was out of range – PFE

35 – EVP – (R) Engine RPM’s too low to test EGR system – EVP

EVR – (O, R, M) EVP sensor signal is/was high – EVR

PFE – (O, R, M) PFE sensor signal is/was high – PFE

38 – Idle Tracking Switch signal was intermittent – ISC

39 – Transmission Torque Converter clutch not engaging – Transmissions

40 – Series Fuel/Air Injection Codes On Vehicles With Dual Oxygen Sensors Refer To The Right Or Rear Sensor Except: 1984-1988 3.8L Engines: Left Sensor

41 – (R) System lean – Fuel control

(M) System was lean for 15 seconds or more (no HO2S switching) – Fuel control

42 – (R) System rich – Fuel control

(M) System was rich for 15 seconds or more (no HO2S switching) – Fuel control

43 – (R) HO2S sensor not reading (run at 2000 rpm’s for 2 minutes and retest – check for HO2S switching)

(M) Was lean at WOT for 3 seconds or more – Fuel control

44 – AIR system inoperative – Air Injection

45 – AIR not Diverting (AIRD) – Air Injection

Electronic Ignition – coil primary circuit failure – Ignition Systems

46 – AIR Bypass (AIRB) not working – Air Injection

Electronic Ignition – primary circuit failure coil 2 – Ignition Systems

47 – Low flow un-metered air (check for small vacuum leaks, injector o-rings, gaskets etc.)

E4OD transmission 4×4 switch/circuit problem – Transmissions

48 – High flow un-metered air (check for large vacuum leak, inlet hoses etc.)

Electronic Ignition – coil primary circuit failure – Ignition Systems

49 – Electronic Ignition – spout signal circuit problem – Ignition Systems

Transmission 1/2 shift problem – Transmissions

51 – Engine Coolant Temperature (ECT) sensor signal is/was too high – ECT

52 – Power Steering Pressure Switch/circuit open – PSP

(R) Did you turn wheel during test ?

53 – Throttle Position sensor too high – TPS

54 – Intake Air Temperature (IAT) or Vane Air Temperature (VAT) signal high – IAT VAT

55 – No or low (under 7.5 V) Key Power to PCM pin 5

56 – Vane Air Flow (VAF) or Mass Air Flow (MAF) sensor high – VAF MAF

Transmission Oil Temperature sensor too high – Transmissions

57 – Intermittent in Park/Neutral/ Switch or Neutral Pressure switch circuit – PNP or Transmissions

1990 Scorpio – Octane jumper installed (information only code – to inform you if it is installed or not)

58 – Idle Tracking Switch (ITS) signal problem ISC

Vane Air Temperature (VAT) sensor out of range or open – VAT

59 – AXOD 4/3 circuit fault – Transmissions

3.0L SHO – Low speed fuel pump circuit problem – Power / Fuel Pump Circuits

Transmission 2/3 shift problem – Transmissions

1990 Scorpio – Idle jumper installed (information only code – to inform you if it is installed or not)

61 – Engine Coolant Temperature (ECT) sensor is or was too low – ECT

62 – AXOD (KOEO only) 3/2 circuit short to ground – Transmissions

AXOD (KOEO AND KOER) 4/3 circuit failure – Transmissions

E4OD excessive converter clutch slippage – Transmissions

63 – Throttle Position Sensor (TPS) signal too low TPS

64 – Intake Air Temperature (IAT) or Vane Air Temperature (VAT) signal low or grounded – IAT VAT

65 – Check intermittent HO2S (signal or ground) – Fuel Control

(R) E4OD truck – cycle OD cancel switch after engine ID is received – Transmissions

1984 3.8L ONLY – O, M Battery voltage high (check for electrical system overcharging)

66 – Vane Air Flow (VAF) or Mass Air Flow (MAF) signal low – VAF MAF

Transmission Oil Temperature (TOT) signal low (possibly grounded) – Transmissions

67 – Park/Neutral circuit fault – PNP

Transmission Manual Lever Position (MLP) sensor circuit – Transmissions

(M) Intermittent Park Neutral Position (PNP) sensor fault – PNP

68 – Idle Tracking Switch (ITS) circuit (possibly grounded) – ISC

Vane Air Temperature (VAT) sensor out of range or grounded – VAT

3.8L AXOD -Transmission Temperature Switch (TTS) open – Transmissions

Electronic Transmission – Transmission Oil Temperature (TOT) sensor was overheated – Transmissions

69 – AXOD transmission (O) 3/2 switch closed (possible short circuit) – Transmissions

AXOD (M) 3/2 switch open (possible short to power) – Transmissions

E4OD 3/4 shift problem – Transmissions

70 – (M) 3.8L AXOD – Data link to instrument cluster fault. Service any other EEC codes, erase memory and retest.

If code is still present refer to instrument cluster diagnosis manual.

71 – (M) 1.9L TBI, 2.3L TBI, 2.5L TBI – ITS signal was grounded when throttle should have been opening ITS – ISC

ISC motor problem or Idle Tracking Switch (ITS) signal wire shorted to ground – ISC

(M) 1.9L MFI – PCM re-initialized. Possible electrical noise, case ground or intermittent VPWR problem – VPWR Diagnosis

(M) 3.8L AXOD – Data link to instrument cluster fault – See code 70

72 – (R) No MAP or MAF change in “goose” test – retest, check for frequency or voltage change – MAP MAF

(M) 1.9L MFI – VPWR circuit to PCM was intermittent – VPWR Diagnosis

(M) 2.3L T/C – PCM re-initialized. Possible electrical noise, case ground or intermittent VPWR problem – VPWR Diagnosis

(M) 3.8L AXOD – Message center data link circuit fault – See code 70

73 – (O) Rerun test, if 73 is still output replace TPS

(R) No Throttle Position Sensor (TPS) change in “goose” test. Must get at least 25% throttle rotation – TPS

74 – Was brake depressed after engine ID was received ?

Brake On Off (BOO) signal open or short to ground – BOO

75 Brake On Off (BOO) signal shorted to power – BOO

76 – Vane Air Flow (VAF) did not respond to “goose” test – VAF

77 – System did not receive “goose” test – see TESTS

78 – (M) VPWR circuit to PCM was intermittent or the PCM is bad VPWR Diagnosis

79 – A/C is on or pin 10 is shorted to power

80 – Series Codes Generally Are Circuit Problems That Could Be Wiring, Rely or Solenoid Related.

Only One Of The Circuits Listed Under The Code Is Used On Each Vehicle. The Fault Is In Whichever Solenoid Or Circuit Is Present On The Vehicle

81 – Boost control solenoid – Solenoids

AIRD solenoid – Solenoids and Air Injection

3.0L SHO – Inlet Air Solenoid – Solenoids

82 – 2.3L TC – Fan Control wire shorted to ground – A/C and Fan Circuits

AIRB solenoid – Solenoids and Air Injection

3.8L SC – Super Charger Bypass Solenoid – Solenoids

83 – High Electro Drive Fan circuit fault – A/C and Fan Circuits

EGR Control solenoid – Solenoids

3.0L SHO – Low Speed Fuel Pump Relay circuit – Power / Fuel Pump Circuits

84 – EGR Vacuum Regulator – Solenoids

EGR cutoff solenoid – Solenoids

EGR Vent solenoid – Solenoids

85 – 2.3L T/C Automatic – 3/4-4/3 Shift solenoid – Transmissions

CANP solenoid (ALL 1989) – Solenoids

(M) 1.9L MFI – System has corrected rich condition – Fuel control

86 – 2.3L or 2.9L Truck – A4LD 3/4 shift solenoid – Transmissions

(M) 1.9L MFI – System has corrected lean condition – Fuel control

87 – (O) Fuel pump circuit fault (check inertia switch) – Power / Fuel Pump Circuits

Vehicles with 2BBL carb – Temperature Compensated Accelerator Pump Solenoid – Solenoids

(M) intermittent in fuel pump primary circuit – Power / Fuel Pump Circuits

NOTE: On some Escorts with automatic seat belts this code is normal IN MEMORY due to the wiring

88 – Throttle Kicker Solenoid – Solenoids

Variable Voltage Choke relay circuit fault – VVC

Fan Control circuit fault – A/C and Fan Circuits

A4LD – Converter Clutch Override solenoid – Transmissions

Electronic Ignition – IDM, DPI or spout circuit fault – Ignition Systems

89 – A4LD – Converter Clutch Override solenoid – Transmissions

AXOD Torque Converter Control solenoid circuit – Transmissions

Exhaust Heat Control (heat riser) solenoid circuit – Solenoids

90 – Series Fuel/Air Injection Codes On Vehicles With Dual Oxygen Sensors Refer To The Left Or Front Sensor Except: 1984-1988 3.8L Engines: Right Sensor

91 – (R, M) System running lean – Fuel control

Transmission SS 1 circuit/solenoid problem – Transmissions

92 – (R) System running rich – Fuel control

Transmission SS 2 circuit/solenoid problem – Transmissions

93 – (O) Throttle linkage binding or bad ISC motor ISC (R) HO2S not reading – Fuel control

Transmission TCC circuit/solenoid problem – Transmissions

94 – AIR system inoperative – Air Injection

Transmission TCC circuit/solenoid problem – Transmissions

95 – (O) Fuel pump: open, bad ground or always on – Power / Fuel Pump Circuits

(R) AIR not Diverting (AIRD) – Air Injection

(M) Possible bad fuel pump ground or open between fuel pump and pin 8 at PCM (Fuel Pump Monitor signal) – Power / Fuel Pump Circuits

96 – (O) Fuel pump monitor circuit shows no power – Power / Fuel Pump Circuits

(R) AIR Bypass (AIRB) not working – Air Injection

(M) (Service 87 code first if present) Fuel pump relay or battery power feed was open – Power / Fuel Pump Circuits

97 – E4OD OD cancel light circuit failure – Transmissions

98 – (R) Did not pass KOEO yet (Get 11 in KOEO first)

Transmission EPC circuit/solenoid failure – Transmissions

99 – (R) ISC needs to learn (Let idle for 2 minutes; Erase memory and retest)

Transmission EPC circuit/solenoid failure – Transmissions

Three Digit Codes: (4)

111 System checks OK

112 (O,M) Intake Air Temperature (IAT) sensor is/was low or grounded – IAT

113 (O,M) IAT sensor is/was high or open – IAT

114 (O,R) IAT sensor out of range – IAT

116 (O,R) Engine Coolant (ECT) sensor out of range – ECT

117 (O,M) ECT sensor is/was low or grounded – ECT

118 (O,M) ECT sensor is/was high or open – ECT

121 (O,R,M) Throttle Position (TP) sensor out of range – TPS

122 (O,M) TP low (possibly grounded or open circuit) – TPS

123 (O,M) TP is/was high or short to power – TPS

124 (M) TP voltage was higher than expected – Fuel control

125 (M) TP voltage was lower than expected – Fuel control

126 (O,R,M) MAP or BARO sensor out of range – “>MAP

128 (M) MAP vacuum has not been changing – check vacuum lines – “>MAP

129 (R) No MAP or Mass Air Flow sensor change during “goose” test – MAP MAF

136 (R) Oxygen sensor not switching/system lean Left or Front HO2S – Fuel control

137 (R) Oxygen sensor not switching/system rich Left or Front HO2S – Fuel control

138 (R) Fault in Cold Start Injector circuit – Fuel control

139 (M) Oxygen sensor not switching Left or Front HO2S – Fuel control

144 (M) Oxygen sensor not switching Single, Right or Rear HO2S – Fuel control

157 (R,M) Mass Air Flow signal is/was low or grounded – MAF

158 (O,R,M) MAF sensor is/was high or short to power – MAF

159 (O,R) MAF sensor is/was out of range – MAF

167 (R) No Throttle Position sensor change in “goose” test (must get at least 25% rotation) – TPS

171 (M) Oxygen sensor not switching – system was at adaptive limits – Single, Right or Rear HO2S – Fuel control

172 (R,M) Oxygen sensor not switching – system is or was lean – Single, Right or Rear HO2S – Fuel control

173 (R,M) Oxygen sensor not switching – system is or was rich – Single, Right or Rear HO2S – Fuel control

174 (M) Oxygen sensor was slow in switching Single, Right or Rear HO2S – Fuel control

175 (M) Oxygen sensor not switching – system was at adaptive limits – Left or Front HO2S – Fuel control

176 (M) Oxygen sensor not switching – system is or was lean Left or Front HO2S – Fuel control

177 (M) Oxygen sensor not switching – system was rich Left or Front HO2S – Fuel control

178 (M) Oxygen sensor was slow in switching Left or Front HO2S – Fuel control

179 (M) Fuel system was rich at part throttle Single, Right or Rear HO2S – Fuel control

181 (M) Fuel system was lean at part throttle Single, Right or Rear HO2S – Fuel control

182 (M) Fuel system was rich at idle Single, Right or Rear HO2S – Fuel control

183 (M) Fuel system was lean at idle Single, Right or Rear HO2S – Fuel control

184 (M) Mass Air (MAF) output higher than expected – Fuel control

185 (M) Mass Air (MAF) output lower than expected – Fuel control

186 (M) Injector pulse width longer than expected or Mass Air Flow (MAF) lower than expected – Fuel control

187 Injector pulse width shorter than expected or Mass Air Flow (MAF) higher than expected – Fuel control

188 (M) Fuel system was rich at part throttle – Left or Front HO2S – Fuel control

189 (M) Fuel system was lean at part throttle – Left or Front HO2S – Fuel control

191 (M) Fuel system was rich at idle – Left or Front HO2S – Fuel control

192 (M) Fuel system was lean at idle – Left or Front HO2S – Fuel control

193 Failure in Flexible Fuel (FF) sensor circuit – Fuel control

194 (M) Perform cylinder balance test to check for inoperative injectors

195 (M) Perform cylinder balance test to check for inoperative injectors

211 (M) Ignition PIP signal was erratic or missing – Ignition Systems

212 (M) Ignition TACH signal was erratic (module/wiring) or SPOUT circuit fault – Ignition Systems

213 (R) Ignition SPOUT or SAW circuit open or shorted – Ignition Systems

214 (M) Error in Cylinder ID (CID) circuit or signal – Ignition Systems

215 (M) Primary circuit failure – ignition coil 1 – Ignition Systems

216 (M) Primary circuit failure – ignition coil 2 – Ignition Systems

217 (M) Primary circuit failure – ignition coil 3 – Ignition Systems

218 (M) IDM signal open or high or left coil pack failure – Ignition Systems

219 (M) SPOUT circuit failure, timing defaulted to 10 degrees – follow code 213 diagnosis

222 (M) IDM open or high or right coil pack failure – Ignition Systems

223 (M) Dual Plug (DPI), SPOUT or IDM circuit fault – Ignition Systems

224 (M) Failure in ignition coil primary circuit – Ignition Systems

225 (R) Knock sensor not tested (ignore if not pinging) – KS

226 (O) Ignition Diagnostic Monitor (IDM) signal fault – Ignition Systems

232 (M) EI primary coil circuit failure – Ignition Systems

238 (M) EI primary circuit failure – ignition coil 4 – Ignition Systems

311 (R) AIR system not working – Single, Right or Rear HO2S – Air Injection

312 (R) AIR not diverting – Air Injection

313 (R) AIR not bypassing – Air Injection

314 (R) AIR inoperative, Left or Front HO2S – Air Injection

326 (R,M) Pressure Feedback EGR shows low pressure EGR not seating or not seating intermittently – PFE

327 (O,R,M) EGR feedback signal is/was low – EVR or PFE

328 (O,R,M) EGR Valve Position (EVP) is/was low – EVR

332 (R,M) EGR did not open/respond during test or if memory code, did not open intermittently – EVR or PFE

334 (O,R,M) EVP sensor is/was high – EVR

335 (O) EGR feedback signal is/was out of range – EVR or PFE

336 (O,R,M) PFE sensor signal is/was was high – “>PFE

337 (O,R,M) EGR feedback signal is/was was high – EVR

338 (M) Cooling system did not heat up (check cooling system / thermostat operation)

339 (M) Cooling system overheated (check cooling system / thermostat operation)

341 (O) Octane jumper installed (information only code to notify you if it is installed)

411 (R) Idle speed system not controlling idle properly (generally idle too high) – ISC

412 (R) Idle speed system not controlling idle properly (generally idle too low) – ISC

452 (M) Vehicle Speed Sensor (VSS) problem

511 (O) No power to PCM pin 1 or bad PCM (processor)

512 (M) Memory power (PCM pin 1) was interrupted – Was battery disconnected ?

513 (O) Replace processor (PCM) (internal failure)

519 (O) PSP switch/circuit open – PSP

521 (R) Wheel not turned during test or PSP problem – PSP

522 (O) Park/Neutral Position (PNP) or Clutch Pedal Position (CPP) circuit fault – PNP

transmission MLP sensor out of range in park – Transmissions

524 Problem in low speed fuel pump circuit – Power / Fuel Pump Circuits

525 (O,M) Park/Neutral Position (PNP) or Clutch Pedal Position (CPP) circuit fault – PNP

528 (M) System shows voltage at pin 10 (is A/C on ?) or pin 30 (PNP, CPP switch) – PNP

529 (M) Data Communications Link to processor failure

Service any EEC codes, erase memory and retest. If code is still present refer to instrument cluster diagnosis manual.

533 (M) Data Communications Link to instrument cluster failure – see 529

536 (O,R,M) Brake On Off open or shorted to ground – BOO

538 (R) System did not receive “goose” test – TESTS

539 (O) System shows voltage at PCM pin 10. Is A/C on ?

542 (O,M) Fuel pump open, bad ground or always on – – Power / Fuel Pump Circuits

543 (O) Fuel pump monitor circuit shows no power – Power / Fuel Pump Circuits

(M) (Service 556 code first if present) Fuel pump relay or battery power feed was open – Power / Fuel Pump Circuits

551 Problem in Intake Manifold Runner Control (IMRC) solenoid/circuit – Solenoids

552 (O) AIRB solenoid/circuit failure – Solenoids

553 (O) AIRD solenoid/circuit failure – Solenoids

554 (O) Fuel Press Regulator Control solenoid/circuit fault – Power / Fuel Pump Circuits

556 (O,M) Fuel pump relay primary circuit fault – Power / Fuel Pump Circuits

557 (O,M) Low speed pump relay primary circuit fault – Power / Fuel Pump Circuits

558 (O) EGR vacuum regulator solenoid/circuit failure – EVR or PFE or Solenoids

559 (O) A/C relay primary circuit fault – A/C and Fan Circuits

563 (O) High Fan Control (HFC) circuit failure – A/C and Fan Circuits

564 (O) Fan Control (FC) circuit failure – A/C and Fan Circuits

565 (O) Canister Purge 1 solenoid/circuit failure – Solenoids

566 (O) transmission 3/4 shift solenoid/circuit – Transmissions

569 (O) Canister Purge 2 solenoid/circuit failure – Solenoids

578 (M) A/C pressure sensor VREF short to ground – A/C and Fan Circuits

579 (M) ACP sensor did not change with A/C on – A/C and Fan Circuits

581 (M) Cooling fan current was excessive – A/C and Fan Circuits

582 (O) Open cooling fan circuit – A/C and Fan Circuits

583 (M) Fuel pump current was excessive – Power / Fuel Pump Circuits

584 (M) Open power ground circuit – Power / Fuel Pump Circuits

585 (M) A/C clutch current was excessive – A/C and Fan Circuits

586 (M) Open circuit in A/C clutch – A/C and Fan Circuits

587 (O, M) Communication problem between PCM and Variable Control Relay Module (VCRM) – Power / Fuel Pump Circuits

617 (M) Transmission shift failure (1/2 shift) – Transmissions

618 (M) Transmission shift failure (2/3 shift) – Transmissions

619 (M) Transmission shift failure (3/4 shift) – Transmissions

621 (O) Solenoid/circuit failure – shift solenoid 1 – Transmissions

622 (O) Solenoid/circuit failure – shift solenoid 2 – Transmissions

624 (O,M) Solenoid/circuit failure -Electronic Pressure Control (EPC) current is high – Transmissions

625 (O,M) Solenoid/circuit failure – Electronic Pressure Control (EPC) current is low – Transmissions

626 (O) Transmission Coast Clutch (CCS) Solenoid/circuit fault – Transmissions

627 (O) Torque Converter Clutch circuit fault – Transmissions

628 (M) Excessive converter clutch slippage – Transmissions

629 (O,M) Torque Converter Clutch circuit fault – Transmissions

631 (O) Overdrive Cancel Light circuit problem – Transmissions

632 (R) E4OD – Transmission Control Switch (TCS) should be cycled once between engine ID and Goose test

633 (O) 4x4L switch should be in 4×2 or 4×4 high for the test

634 (O,M) Park/Neutral Position (PNP) or Clutch Pedal Position (CPP) circuit fault

Electronic shift transmission – Manual Lever Position (MLP) sensor out of range in PARK – Transmissions

636 (O,R) Transmission Oil Temperature (TOT) sensor out of range – Transmissions

637 (O,M) TOT sensor is/was high or open – Transmissions

638 (O,M) TOT sensor is/was low or grounded – Transmissions

639 (R,M) Transmission Speed sensor (TSS) circuit fault – Transmissions

641 (O) Transmission solenoid/circuit failure Shift Solenoid 3 – Transmissions

643 (O)(M) Torque Converter Clutch (TCC) circuit – Transmissions

645 (M) Transmission 1st gear failure – Transmissions

646 (M) Transmission 2nd gear failure – Transmissions

647 (M) Transmission 3rd gear failure – Transmissions

648 (M) Transmission 4th gear failure – Transmissions

649 (M) Transmission EPC system failure – Transmissions

651 (M) Transmission EPC solenoid/circuit fault – Transmissions

652 (O) Torque Converter Clutch (TCC) circuit fault – Transmissions

654 (O) Transmission selector not in PARK – Transmissions

656 (M) Torque Converter Clutch (TCC) slip – Transmissions

657 (M) Transmission temperature was excessive – Transmissions

998 (R) Did not pass Key On Engine Off test yet (Get 111 in KOEO first)

Abbreviations & Definitions: (5)

ACT: Air Charge temperature sensor. Senses the temperature of air entering the engine.

BP: Barometric Pressure (see MAP)

EEC: Electronic Engine Control Fords Engine management systems.

ECT: Engine Coolant Temperature Sensor. Senses the coolant temperature.

EGR: Exhaust Gas Re-circulation Valve. Allows some harmful exhaust gasses to be re-burned through the engine for emissions purposes.

EVP: EGR Valve Position sensor.

FPR: Fuel Pressure Regulator. A vacuum actuated device to keep constant fuel pressure.

HEGO: Heated Exhaust Gas Oxygen sensor (O2 sensor, EGO, oxygen sensor). Detects how much oxygen is in the exhaust to determine rich or lean running conditions.

IAC/ISC: Idle Air Control (Idle Speed Control) motor. An electric valve which allows air to enter the intake at idle, changing the idle speed.

IAT: Intake Air Temperature (see ACT)

KS: Knock Sensor. Detects Engine Knock (vibration) to allow computer to adjust timing accordingly

KOEO (O): Key On, Engine Off. Type of diagnostics test.

KOER (R): Key On, Engine Running. Type of diagnostics test.

MAF: Mass Air Flow Sensor

MAP: Manifold Absolute Pressure sensor.

MIL: Malfunction Indication Lamp (Check Engine Light on Dash)

MLP: Manual Lever Position.

OBD: On Board Diagnostics (the computers diagnostics system)

PCM: Power train Control Module (the computer)

PIP: Computer Input for Timing Indication.

PNP: Park/Neutral Position Sensor. Senses if an automatic is in park, or a standard is in neutral. Also referred to as a Neutral Safety Switch.

SPOUT: Spark Output. It is a distributor to allow manual control for ignition timing. It is also the output signal of the distributor to the PCM.

TFI: Thick Film Ignition. A Ford Ignition module, which is found at the base of the distributor.

TP (TPS): Throttle Position Sensor. Tells the PCM how much gas should be entering the Engine.

VSS: Vehicle Speed Sensor.

TPS Calibration: (6)

Warm the engine up. Shut engine off, and turn ignition on. With a voltmeter on the appropriate setting, probe the TPS center wire with the (+) probe, and ground the (-) probe. Adjust the throttle plate adjustment screw so the voltmeters reading is 0.9 to 1.0V DC.

Base Idle Adjustment: (7)

This essentially is an alternate test for the TPS Calibration. The base idle is computer controlled via the Idle Air Control (IAC) motor. To do this crude base adjustment, warm the engine up. Unplug the IAC electrical connector. Restart the engine (if it doesnt start, screw the throttle plate adjustment screw in, until it starts). Once the vehicle is running, adjust the throttle plate adjustment screw until the idle reaches 650RPM. Plug the IAC electrical connector, and restart the engine. The idle should settle to 850-950RPM. Note that it is best to use an accurate tune up tachometer, not the stock gauge.

Oxygen Sensor Testing: (8)

There may be three wires on the O2 sensor; two gray wires and one black. The black should read ground. One gray wire should read 12V with the ignition on, and the other gray wire is the one we are after. Probe this wire with the engine warm, and running with a voltmeters (+) probe, and ground the negative probe. While the vehicle is running, the reading should be approximately 0.5V. A reading below this indicates a lean air fuel mixture; a reading above this indicates a rich mixture. If no reading is present, and all connections are good, the sensor is probably in need of replacement.

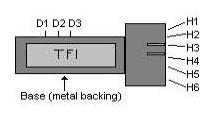

TFI Module Resistance Test: (9)

The TFI module may be removed, and tested for resistance between terminals to determine complete failure. Often stock TFI modules only partially fail when engine temperatures get warm, and the vehicle runs rough then dies. The vehicle then restarts, and runs for 20 seconds then dies again. This is a defect, which affected ALL TFI modules before 1995, although some do not seem to be very problematic (this is often causes codes 14 and 18).

- D1 to H1 12.8K

- D1 to H2 17.4K

- D1 to H3 1000

- D1 to H4 11.5K

- D1 to H5 4.2K

- D1 to H6 0.0K

- D2 to H1 1.2K

- D2 to H2 5.8K

- D2 to H3 12.6K

- D2 to H4 100

- D2 to H5 15.8K

- D2 to H6 11.6K

- D3 to H1 100

- D3 to H2 4.7K

- D3 to H3 13.7K

- D3 to H4 1200

- D3 to H5 16.9K

- D3 to H6 12.7K

- D1 to D2 11.5K

- D1 to D3 12.6K

- D2 to D3 1100

- D1 to BASE 0.0K

- D2 to BASE 12K

- D3 to BASE 13.1K

ECT and ACT Test: (10)

There are two wires across these sensors. Tests can be done with the engine off (resistance) or running (voltage). With the engine cold, probe the two wires with a multi-meter. There should be some resistance between the two (relative to the chart below). Set meter to volts and start the engine. The ECT with gain temperature as the engine runs, eventually the temperature will drop when the thermostat opens. This test will tell you WHEN THE THERMOSTAT ACTUALLY OPENS! The ACT with generally not vary much. The ACT reading should at first correspond to the air temperature outside the vehicle, with acceptable variation for heat given off the engine. These tests could be performed against an accurate thermometer to test the accuracy; however, there is an allowable +/- 15% tolerance for the numbers.

| Engine Coolant Temperature Sensor | |||

| Temperature | Voltage | Resistance | |

| F° | C° | Volts | K ohms |

| 302 | 160 | 0.12 | 0.54 |

| 267 | 131 | 0.20 | 0.80 |

| 250 | 120 | 0.30 | 1.18 |

| 230 | 110 | 0.36 | 1.55 |

| 212 | 100 | 0.47 | 2.07 |

| 194 | 90 | 0.61 | 2.80 |

| 176 | 80 | 0.80 | 3.84 |

| 158 | 70 | 1.04 | 5.37 |

| 140 | 60 | 1.35 | 7.60 |

| 122 | 50 | 1.72 | 10.97 |

| 104 | 40 | 2.16 | 16.15 |

| 86 | 30 | 2.62 | 24.27 |

| 68 | 20 | 3.06 | 37.30 |

| 50 | 10 | 3.70 | 58.75 |

| 32 | 0 | 3.97 | 65.85 |

| 14 | -10 | 4.42 | 78.19 |

| -4 | -20 | 4.87 | 90.54 |

| -22 | -30 | 4.89 | 102.88 |

| -40 | -40 | 4.91 | 115.23 |

TFI Timing: (11)

All TFI systems are timed in the same manor. The engine must be brought up to operating temperature, and must be idling within spec. With the engine off the SPOUT connector must be removed. The SPOUT connector is a yellow wire near the distributor that either pulls apart with a wire connector, or has a little block that is removed (much like a spade fuse). This connector, or block stops the PCM from advancing the timing so an accurate base timing can be tested (with the SPOUT plugged in, base timing could be off as much as 10 degrees). Connect a timing light as usual, (+) and (-) leads on the battery, and the pickup connector on the #1 cylinders spark plug lead. Mark off 10 degrees (unless the vehicle emission label says otherwise) wherever it is located on this vehicle (often on the crank shaft pulley, or under a rubber boot at the top of the transaxle). Start the vehicle and check timing. Adjust the distributor as necessary, and reinstall the SPOUT connector.

IAC Cleaning/Testing: (12)

The IAC is usually a cylindrical unit attached to the upper intake manifold. This unit electrically controlled by the computer, and allows air to flow into the intake at idle, bypassing the throttle plate. The extra air is accompanied by extra fuel to bring the idle up to proper speed, and when cold, allows a high idle condition. These units may become dirty, and need cleaning. Many idle and stalling issues tend to be blamed on these units. Cleaning is achieved by removing the electrical connector, and two screws holding it on. Once off of the vehicle, clean with throttle body cleaner (or a good carburetor cleaner). Continue cleaning until unit is clean, like new; reinstall unit. This is also a good time to clean the intake, and EGR ports (if applicable).

Testing may be achieved by bringing the engine to operating temperature, noting the idle speed (should be within spec). Unplug the units electrical connector, and the idle should drop to about 650 RPM. When the unit is reinstalled, it should return to normal idle speed. If the vehicle does not idle at proper RPM (too low), there are no vacuum leaks, and the TPS calibration is correct, than the unit is most likely faulty.

FPR Testing: (13)

An essential part of the EEC-IV system is the fuel system. Often, the fuel system is blamed for faults which actually occur elsewhere; however, a simple test can test many components. A high pressure fuel tester must be connected to the fuel relief valve on the fuel rail (usually a Schrader valve). First relieve fuel system pressure, then attach the tester. Next, turn the key on (engine off) to prime the fuel system. There should be 36-42PSI of pressure. Start the engine. The pressure at idle should remain within the same range. Rev the engine a few times to ensure fuel pressure remains constant. Excess pressure usually determines a faulty FPR. Too little pressure could be the FPR, fuel filter, fuel pumps, or a leak.

Knock Sensor: (14)

The knock sensor is a device used to detect engine pinging (vibrations) so that the computer can advance or retard riming for optimal performance. Because the knock sensor is sensitive to vibrations, it must be tightened to proper torque, and not have anything vibrating against it. Additionally it has an insulation that must remain in good shape. Generally if the engine code detects the KS, the sensor is usually bad unless a visual or electrical inspection proves otherwise.

MAP Testing: (15)

Speed density computers use a MAP sensor (other usually use a MAF). The MAP sensor measures Barometric Pressure (BP) when the key is first turned (this accommodates for altitude). When the engine is running it takes the BP and subtracts the pressure caused by the engine (pistons) to send a frequency (in Hz) to the computer. Testing requires two tools: a vacuum pump (with gauge) a 5V DC supply and a Digital multi-meter with a frequency (Hz) setting. There are three electrical connectors on the sensor. The one closest to the Vacuum lines is input from the computer, the middle wire is signal output to the computer, and the wire furthest from the vacuum line is the ground line (which grounds through the computer). To test the unit, it must be removed from the vehicle, have vacuum applied to it, than measure the frequency across the ground and signal (middle) wires, as per the chart below while 5V DC is applied to the input wire (closest to the vacuum line). The list below is +/- 3Hz.

| in-Hg | kPa | Hz |

| 0 | 0 | 159 |

| 3 | 10.2 | 150 |

| 6 | 20.3 | 141 |

| 9 | 30.5 | 133 |

| 12 | 40.6 | 125 |

| 15 | 50.8 | 117 |

| 18 | 61.0 | 109 |

| 21 | 71.1 | 102 |

| 24 | 81.3 | 95 |

| 27 | 91.5 | 88 |

| 30 | 101.6 | 80 |